Powered handling and transport systems

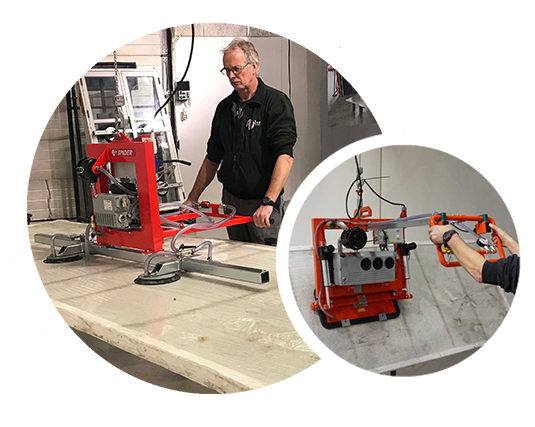

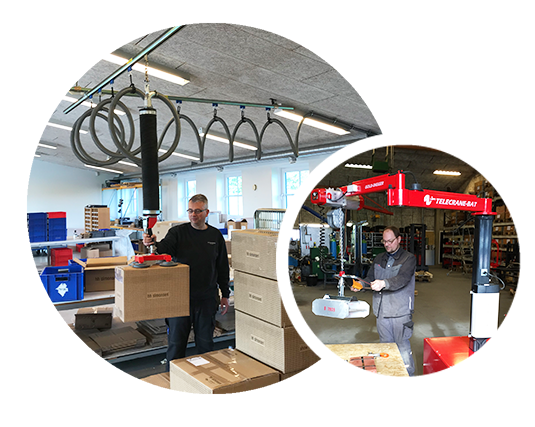

Nearly all modern industries require also long range transportation of various goods. Not all products can be operated by forklift; therefore we offer various solutions to ensure high ergonomics in station-to-station transportation.

Depending on clients needs we offer either standard solution, focused on widely used types of products and individual handling aids that allow us to satisfy more complex clients needs. Customized load attachments in the shape of roller platforms, forks, hooks and gripers let us operate with shelves, filling & conveying systems, centrifuges, pallets, roller tables, etc. with high ergonomics.

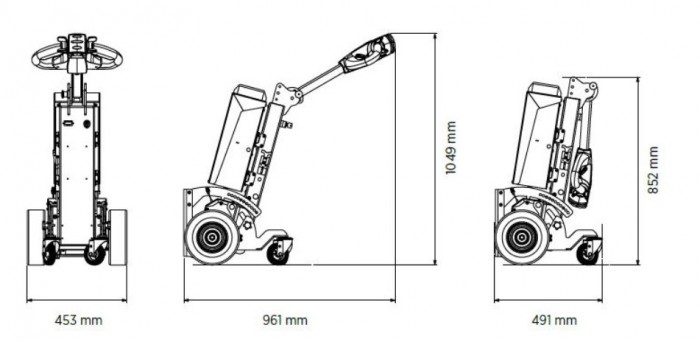

In addition to our lifting aids we offer all types of effortless platform carts with patented drive. With payload up to 500 kg, we ensure that transporting heavy goods is not only more efficient, but also significantly safer.